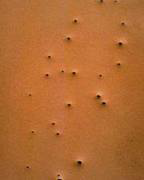

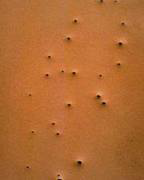

Occasionally when you inspect a cured resinous coating or topping you see areas of the floor dotted with pin holes, dried bubbles, or the volcano look of exploded bubbles. Rarely is this across the entire floor, typically it’s is in isolated sections. While there are various reasons for this phenomenon ranging from environmental conditions such as air movement over the slab and coating to the formulation of the material, over rolling while installing, mixing at high rate of speed or with an inappropriate mix blade all of which can introduce air into the final product and produce this effect. But all of these too can be controlled, either by the manufacturer when formulating or the applicator when installing. The most common reason for this issue is known as “outgassing” in our industry defined as: the slow escape of air from a concrete slab while the coating or overlayment is curing, resulting in pinholes in the finished coating.

As we know concrete is a porous, permeable material with microscopic air pockets resulting from the hydration process when it cures. While it is possible to “densify” the surface of the concrete by power troweling and/or by adding “cure and seals” etc…, this process is negated by the need when applying non-breathable coatings to open up the surface by shot blasting, grinding or other mechanical means to obtain a clean abraded surface to which the coating can bond to. Such preparation greatly increases the likelihood of air to escape from the slab. If the topping is impermeable, and the vapor pressure is high enough, such escaping air will likely result in pinholes.

What causes this entrapped air to want to escape? Its basic physics in that air expands as it is heated. Several factors lead to heating of the entrained air: the curing of the coating is an exothermic reaction that generates heat (the thicker the coating, the more heat is generated); if the slab is colder than the air space above it, then a temperature gradient exists to cause air to want to flow from the colder slab to the warmer air. A third factor at work here would be air circulation over the slab that will also increase the tendency of the air to want to escape the slab.

So how is outgassing prevented? The most widely used preventative measure is to try sealing the concrete after surface preparation with a low viscosity, deep penetrating primer. Note that the primer will only be effective in sealing the surface once it dries at least tack free; otherwise, passageways will still be left in the primer allowing air to escape into the top coats. Depending on the porosity of the concrete, however, one thin sealer coat cannot always be expected to completely seal the substrate. And especially with clear primers, it is very difficult to judge whether the concrete has been completely sealed.

A more effective means of preventing outgassing is to reverse the flow of air by making sure the slab is at an equal or greater temperature than the overhead air, thereby reversing the air flow. To do this requires either, pre-heating the slab by direct heat or increasing the air temperature sufficiently to bring the slab temperature up to the ambient conditions, then shutting off the heat in the room. Reducing any external air flow (from open doors, windows, and HVAC units) is also highly recommended to help minimize outgassing. If these two conditions are met, the primer step can be safely eliminated for self-priming overlayments; otherwise, priming is strongly recommended prior to applying top coats.

Other means of minimizing (or completely eliminating) outgassing is by installation of a permeable top coat. For example, drier troweled mixes, unlike resin-rich formulas, are porous enough to allow air to escape. Of course, this porosity greatly reduces the beneficial effects of a sealed top coat that prevents liquids and other contaminants from entering the substrate, particularly in wet environments. Some water-based primers that are breathable have been offered as a solution to outgassing, but, these are only effective if the top coats are also “breathable”. A more commonly used application method is to apply toppings by the slurry/seed method, where an aggregate such as sand is applied to refusal. Such displacement of the air by the added aggregate helps to reduce chances for pin-holing from outgassing.

In the warm and dry environment of our desert West and Southwest, timing of the application whether early in the morning or late in the evening and avoiding as much as possible direct exposure to sunlight can prevent or at least minimize this effect. The use of a pigmented primer is most helpful in identifying those troublesome areas that can be rectified early on usually by re-priming them. The opposite is true if the slab is warmer than the air above it, so in cold environments warm air in the slab pulls cold air above it downward into the slab, in essence the reverse of outgassing and the problem is avoided.

Repairing outgassing issues requires recoating with the same material and since these coatings have a limited shelf life they are usually batch manufactured for each job. Thus it is difficult to just apply solely over the affected area without it looking like a patch after curing. So to correct it aesthetically and functionally it may require the entire area or at least that entire room or area that is isolated from the rest of the floor to be recoated. This is quite the expense in time, materials and labor.

Being aware of the conditions that lead to outgassing is the first priority in preventing it. Following these precautions in planning your installations can greatly reduce the risk of outgassing, thereby saving you the expense and aggravation of rectifying the problem after the fact.

A unique project was completed in Mid-2014 at the Grand Coulee Dam, located in Washington State. The contractor was charged with the task of coating the entire draft tube surface with ICO Gel totaling a 40’x40’ square structure.

A unique project was completed in Mid-2014 at the Grand Coulee Dam, located in Washington State. The contractor was charged with the task of coating the entire draft tube surface with ICO Gel totaling a 40’x40’ square structure.

The coating concrete surface of the draft tube with ICO Gel prevented further wear, limited further degradation and erosion, with surface flow coefficients greatly improved. The USBR is confident in the overall outcome and is therefore proceeding with the same coating on the second unit draft tube in January 2016 and third in 2017-18.

The coating concrete surface of the draft tube with ICO Gel prevented further wear, limited further degradation and erosion, with surface flow coefficients greatly improved. The USBR is confident in the overall outcome and is therefore proceeding with the same coating on the second unit draft tube in January 2016 and third in 2017-18.